One of the biggest mental hurdles for potential Electric Vehicle owners to overcome is the charging time. While charging infrastructure continues to improve, battery technology continues to improve, we would all like fast-charging times to be reduced.

As you recharge an EV, the speed will taper off dramatically as the state of charge increases to protect the battery. It’s not uncommon to see the promised 30-minute top-ups often stretch out to 40 or 45 minutes. This is often due to the manufacturer being sensitive to battery longevity.

One of the biggest challenges when recharging batteries rapidly is the thermal inconsistencies across cells in the pack. When you push massive amounts of power into a battery pack via a fast charger, the cells heat up, and not uniformly. This thermal imbalance is a key reason why charging power may be throttled.

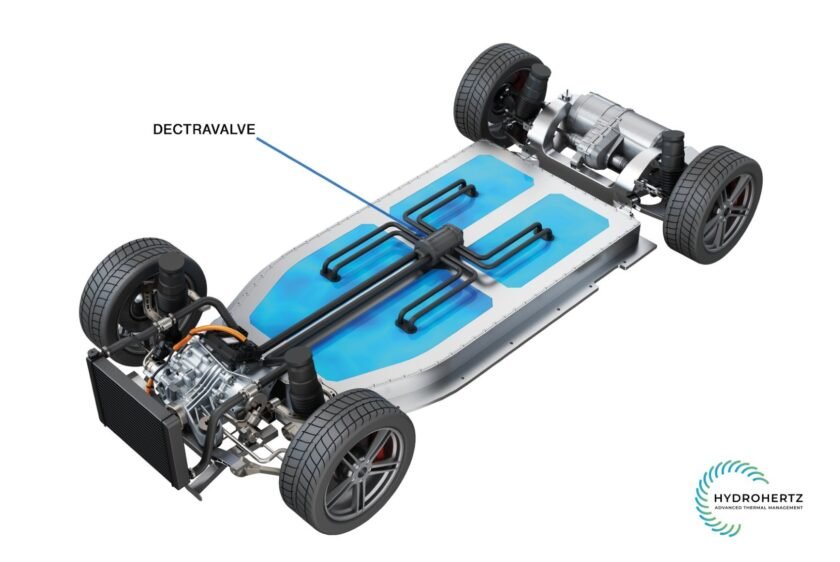

A British company, Hydrohertz, has just announced a new technology that promises to solve this thermal management problem. Their innovation is called the Dectravalve, which has the potential to deliver a consistent 10-minute fast charge time. This isn’t a new battery chemistry, but a clever engineering solution to get the most out of the batteries we already have.

If cells push past a critical temperature (typically around 50°C), it triggers an automatic throttling of charging power. This is a safety measure to prevent ‘lithium plating,’ which causes internal cell damage and drastically shortens the overall life of the battery pack. In today’s EVs, the temperature difference across the pack can easily exceed 12°C, meaning the hottest cell dictates when the entire system must slow down.

– Advertisement –

You’ll often get blistering fast speeds for the first 10-20% of the charge, only for the charging curve to look like a mountain range on a gentle slope for the remainder of the session. The system is protecting itself from a thermal weak spot. Hydrohertz saw this issue and realised the true bottleneck wasn’t the charging station or the battery chemistry, but the thermal management system itself.

The core of Hydrohertz’s innovation is the Dectravalve, a compact, intelligent, multi-zone valve system. Unlike traditional EV cooling systems that try to treat the entire battery pack as a single unit, the Dectravalve is capable of delivering incredibly precise, targeted heating or cooling to individual modules within the pack.

It acts as a brain for the thermal fluids, directing coolant exactly where it’s needed in four or more completely independent zones. This eliminates the ‘shared circuit’ problem, where warm coolant from one section of the pack could inadvertently heat up another, creating a thermal domino effect. The result is a clean, controlled thermal environment right across the pack.

“The Dectravalve solves a fundamental problem of EV battery thermal management systems – how to achieve true independent zone control of temperature without the complexity, weight, and energy waste of multiple valve arrays. Our innovation is elegantly simple: a single, digitally controlled unit that can manage four or more cooling zones separately. With Dectravalve, each cooling zone is completely independent, so coolant flows from the pump to the battery and back again in a specific loop. There are no unwanted, efficiency-sapping, leaks of warm coolant between zones.

“With Dectravalve, there is no ‘shared circuit’ where one overheated cell group could cause wider thermal contamination. This stops there being a thermal “domino effect” where hotspots quickly spread, and also ensures that each section of the battery receives exactly the cooling it needs. The result is a clean, controlled thermal environment right across the pack, with zero compromise or crossover.

“What makes this genuinely breakthrough technology is the precision it delivers. In our testing, we kept battery cells within just 2-3°C, which translates directly into faster charging, longer battery life, and critically, enhanced safety. We’ve essentially created a thermal management system which thinks and responds as quickly as possible – and one that is completely agnostic to cell chemistry too.”Hydrohertz CTO Martyn Talbot

“The automotive industry has been waiting for battery technology to catch up with consumer expectations, but progress has been slow and expensive. A new chemistry can take a decade to develop and require billions in investment. What we’ve done is take a different approach – we’ve dramatically improved how existing batteries perform by perfecting the thermal management of them.

This is a cost-effective solution that delivers game-changing results: consistent 10-minute charging, longer range, extended battery life, and enhanced safety. For OEMs, this means better, more useable EVs now, without waiting for the next generation of battery technology. But when that technology does arrive, Dectravalve will optimise it too. The impact for both car makers and consumers is set to be transformative.”

Paul Arkesden, CEO of Hydrohertz,

Independent Testing

In independent testing conducted by leading battery experts at the Warwick Manufacturing Group (WMG), a 100kWh Lithium Iron Phosphate (LFP) EV battery equipped with Dectravalve performed spectacularly under pressure.

During an ultra-fast charging test, the system kept its hottest cell below 44.5°C, maintaining a temperature difference of only 2.6°C across the whole pack. Because the Dectravalve-equipped battery never left the optimum high-power zone, it was able to keep every module operating at peak efficiency.

The testing demonstrated that charging times can be slashed by an incredible 68%. This means a typical 30-minute 10-80% charge on a 350kW fast charger could now drop to a mere 10 minutes. This is a monumental shift that finally puts EV refuelling on a par with stopping for petrol or diesel, eliminating one of the last major points of consumer resistance in the Aussie market.

techAU’s thoughts

From what we understand, this technology has not yet been implemented in a vehicle; therefore, results should be considered with that in mind. The rendered graphics included with the release show the Dectravalve on top of the battery pack, which is likely to impact in-cabin space for occupants, and there’s no indication of what additional cost would be introduced from this.

These are all important considerations before we get too excited by this. Often, technology in the lab fails to translate to production due to the economic viability, with cost and complexity not making sense for a practical application. There may be specific models, or price points where this additional complexity is justified and for those owners, reduced charging times will be welcome.

For more information, head to hydrohertz.com